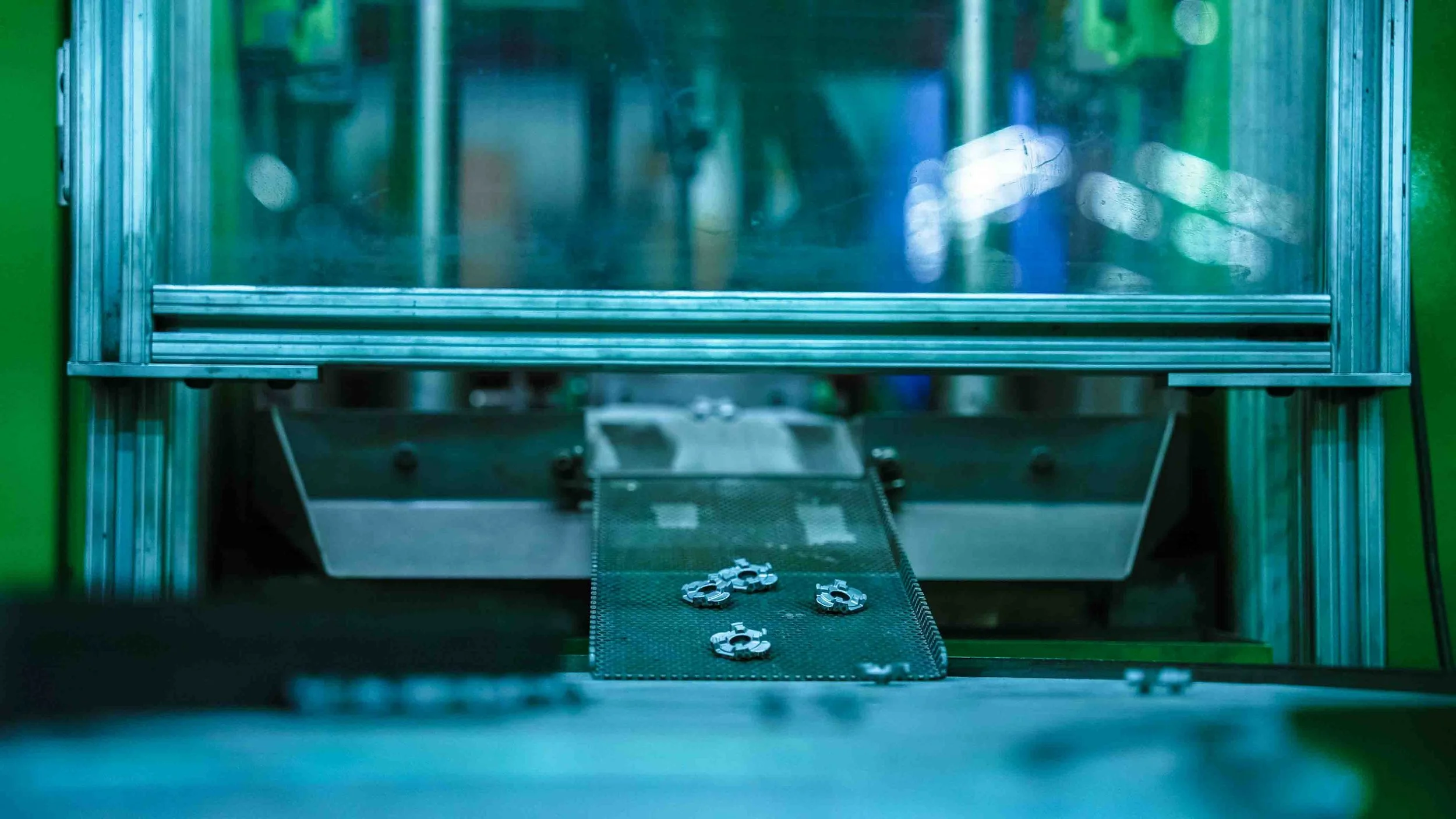

At Volunteer Sintered Products, components are manufactured by compacting metal powder and heating it until solid. This process reduces waste, lowers production costs, and delivers strong, precise parts. Widely used across various types of industrial machinery and equipment, these components enhance performance, improve efficiency, and support reliable operation in multiple sectors.

Construction & Agricultural Machinery

Engineered Strength & Reliable Performance

Sintered and powder metal components are manufactured by compacting metal powder into precise shapes and then heating (sintering) until the material solidifies into a strong, high-performing part. This efficient manufacturing method significantly reduces material waste and lowers production cost while maximizing precision and mechanical strength.

Request a quote or ask a question

Construction And Agricultural Machinery Parts

Sintered metal components are created through powder metallurgy, a process where fine metal powder is shaped and heated until it forms solid, durable parts. This efficient manufacturing approach reduces material waste, lowers production costs, and produces components with excellent precision and quality. Known for their strength, durability, and cost-efficiency, these parts are utilized across a variety of sectors—including industrial machinery, electronics, aerospace, and general manufacturing—delivering reliable and high-performance solutions for diverse applications.

With the latest manufacturing technologies, even highly complex and detailed shapes can be produced while minimizing material waste. This makes sintered metal components an environmentally friendly and cost-efficient option for businesses looking for precision-engineered, high-performance parts and dependable solutions across various industrial sectors.

Why Choose Construction and Agricultural Machinery?

Our Construction and Agricultural Machinery Solutions

We provide high-quality custom machinery components designed to meet industry standards. From small, detailed parts to larger, durable components, our precision manufacturing ensures accuracy and consistency in every piece. Each component is built for strength, reliability, and long-lasting performance, making them ideal for a variety of industrial applications.

Our team collaborates closely with clients to fully understand their requirements and deliver tailored machinery solutions. From concept to final product, we ensure you receive the perfectly engineered component for your application—on time, within budget, and consistently meeting the highest quality standards nationwide.

How We Work

A Simple 6-Step Process for Quality Sintered Metal Parts

Step 1: Consultation – Understanding your needs

Step 2: Design & Planning – Creating accurate solutions

Step 3: Powder Preparation – Blending quality powders

Step 4: Compacting – Pressing into shape

Step 5: Sintering – Heating for strength

Step 6: Finishing & Delivery – Final touch & supply

Conversion Projects Process

Our unique conversion engineering process saves you money, reduces your time to market, and improves your precision components.

Why Choose Us

Choosing us means you get reliable quality, expert support, and cost-effective solutions for all your powder metal requirements. Using advanced manufacturing technology and established powder metallurgy methods, we produce sintered metal parts that deliver superior performance, durability, and precision for a wide range of industrial applications.

Our commitment is to build long-term relationships with clients by providing consistent service, competitive pricing, and customized sintered metal solutions for a wide range of industrial needs. When you partner with us, you gain a trusted ally dedicated to your business success, wherever you are. We offer:

Precision-engineered sintered metal parts built to last

Efficient, budget-friendly solutions for powder metallurgy and industrial machinery

Tailor-made designs crafted to meet your specific requirements

Dependable nationwide support with outstanding customer care

Where to Find Us

You can find Volunteer Sintered Products conveniently located in Tennessee, where we operate our state-of-the-art manufacturing facility. Our location allows us to efficiently serve clients across the United States and beyond, providing reliable delivery and responsive support. Whether you’d like to discuss a new project, request a quote, or visit our facility, our team is always ready to assist you. Connect with us today to learn more about how our sintered metal engineering solutions can meet your production needs.

With decades of experience and modern technology, we ensure that every collaboration leads to long-term success. Reach out today and discover how our sintered metal expertise can power your next project.

Frequently Asked Questions

-

They are used in various machines and equipment to provide strength, precision, and durability for construction and farming tasks.

-

Yes, these components are engineered to withstand heavy loads and long-term use in industrial and agricultural machinery.

-

They are made using powder metallurgy, where fine metal powder is pressed into shape and heated to form solid, durable parts.

-

Absolutely, they can be tailored to meet the exact requirements of construction, farming, or industrial equipment.

-

They offer high durability, precise performance, cost-effectiveness, and reliability for all types of construction and agricultural machinery.