Sintered Metal Engineering Solutions for High-Performance Components

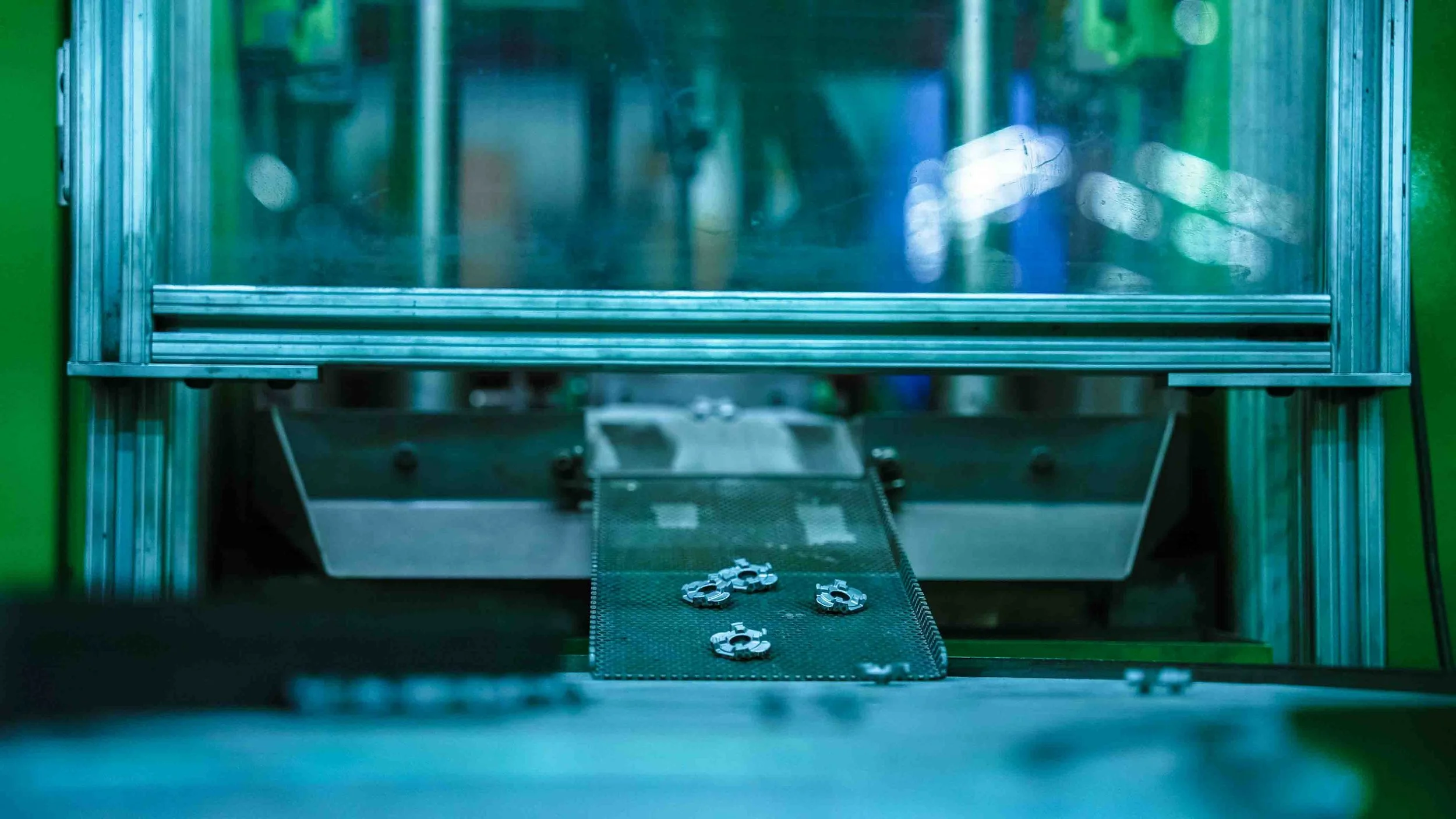

At Volunteer Sintered Products, we specialize in advanced sintered metal engineering solutions designed for durability and precision. Our expertise ensures high-performance components that meet the toughest industrial standards. Partner with us for reliable, engineered metal parts built to perform.

Precision Sintered Metal Engineering You Can Trust

At Volunteer Sintered Products, our sintered metal engineering process combines innovation, quality materials, and advanced technology to deliver components with exceptional strength and accuracy. Whether you need custom parts or large-scale production, our team ensures consistent performance and superior reliability for every application. We proudly serve a wide range of industries, including automotive, construction and agricultural machinery, powersports vehicles, and outdoor power equipment, providing tailored solutions to meet each sector’s unique demands.

Request a quote or ask a question

Custom Sintered Metal Solutions for Every Industry

Engineering Strength, Precision, and Performance in Every Part

At Volunteer Sintered Products, we take pride in delivering custom sintered metal engineering solutions that combine strength, precision, and efficiency. Our team works closely with clients to design and manufacture components that meet exact specifications while maintaining cost-effectiveness and durability. Using advanced powder metallurgy techniques, we produce parts that perform reliably under demanding conditions.

Serving industries such as automotive, construction and agricultural machinery, powersports vehicles, and outdoor power equipment, our sintered metal products ensure consistent performance and long service life. With a focus on quality, innovation, and customer satisfaction, we continue to set new standards in the sintered metal engineering industry.

Innovative Sintered Metal Engineering for Superior Performance

At Volunteer Sintered Products, innovation drives everything we do. Our sintered metal engineering expertise allows us to create complex, high-precision components that traditional manufacturing methods can’t easily achieve. Each product is engineered to deliver maximum strength, accuracy, and dependability, even in the most demanding environments. We utilize cutting-edge technology and rigorous quality control processes to ensure every part meets exacting standards. Whether you need prototypes or full-scale production, our team provides end-to-end support to bring your ideas to life. With decades of experience and a commitment to excellence, we help our partners achieve superior performance and long-term value through precision-engineered metal solutions.

New Design Process

To create the perfect component for your application, you’ll go through our hands-on “new design” process.

Step 1: Process and Design Collaboration

Step 2: PFMEA and Part Simulations

Step 3: Provide Prototypes for feasibility validation

Step 4: Refine design and optimize material selection

Step 5: Production tooling

Step 6: Product Qualification & Production Validation & Testing

Industries we serve

To create the perfect component for your application, you’ll go through our hands-on “new design” process.

Automotive Industry

Precision powder metallurgy parts enhance automotive systems with durable, high‑strength components for reliable top performance.

Construction & Agricultural Machinery

Precision powder metallurgy parts enhance construction and agricultural machines with durable, high‑strength components for extra efficiency.

Powersports Vehicles

Precision powder metallurgy parts enhance powersports vehicles with durable, high‑strength components for reliable performance offroad.

Outdoor Power Equipment

Precision powder metallurgy parts enhance outdoor power equipment with durable, high‑strength components for performance in yard tasks.

Sintered Metal Conversion Process

Our sintered metal conversion process transforms traditional components into high-performance, cost-efficient sintered metal parts.

Why Choose Volunteer Sintered Products

At Volunteer Sintered Products, we combine decades of experience with advanced sintered metal engineering to deliver products that exceed expectations. Our commitment to quality, precision, and innovation ensures every component is manufactured to the highest standards. We work closely with clients to provide tailored solutions that optimize performance, reduce costs, and enhance reliability. With a focus on consistency, on-time delivery, and exceptional customer support, we are the trusted partner for industries that demand durability and precision in every part.

Our skilled engineers and technicians leverage advanced powder metallurgy techniques to design and produce parts that meet the most demanding requirements. Every project is approached with a problem-solving mindset, ensuring optimal material selection, strength, and efficiency. We take pride in turning complex challenges into reliable, cost-effective solutions that perform consistently in real-world applications.

Serving industries such as automotive, construction and agricultural machinery, powersports vehicles, and outdoor power equipment, we deliver components built for lasting performance. From concept to completion, our focus remains on precision, innovation, and long-term results, making us the preferred choice for sintered metal components across diverse sectors.

Where to Find Us

You can find Volunteer Sintered Products conveniently located in Tennessee, where we operate our state-of-the-art manufacturing facility. Our location allows us to efficiently serve clients across the United States and beyond, providing reliable delivery and responsive support. Whether you’d like to discuss a new project, request a quote, or visit our facility, our team is always ready to assist you. Connect with us today to learn more about how our sintered metal engineering solutions can meet your production needs.

With decades of experience and modern technology, we ensure that every collaboration leads to long-term success. Reach out today and discover how our sintered metal expertise can power your next project.

Frequently Asked Questions

-

Sintered metal engineering is a manufacturing process that uses powdered metal compacted under high pressure and heated to form strong, precise, and durable components. This method offers excellent strength, consistency, and minimal material waste.

-

Sintered metal parts provide high strength, close dimensional accuracy, cost efficiency, and the ability to produce complex shapes. They also deliver consistent performance and reduced machining requirements.

-

Sintered metal components are widely used in automotive, construction and agricultural machinery, powersports vehicles, and outdoor power equipment due to their durability and precision.

-

Yes, sintered metal parts can be fully customized to meet specific requirements. Our engineering team designs components based on your material, shape, and performance needs.

-

Yes, the process generates minimal waste and uses materials efficiently, making it an eco-friendly manufacturing method.