Insights

Powder Metallurgy vs Forging: Key Differences, Pros, and Cons

Powder metallurgy and forging are both reliable methods for producing durable metal parts. Powder metallurgy excels in precision, complex shapes, and low waste, while forging offers superior strength for high-stress applications.

Powder Metal Solutions: Key Uses and Advantages Explained

Powder metal solutions deliver high-strength, precision parts with minimal waste—enabling complex designs, lower costs, and consistent performance across industries.

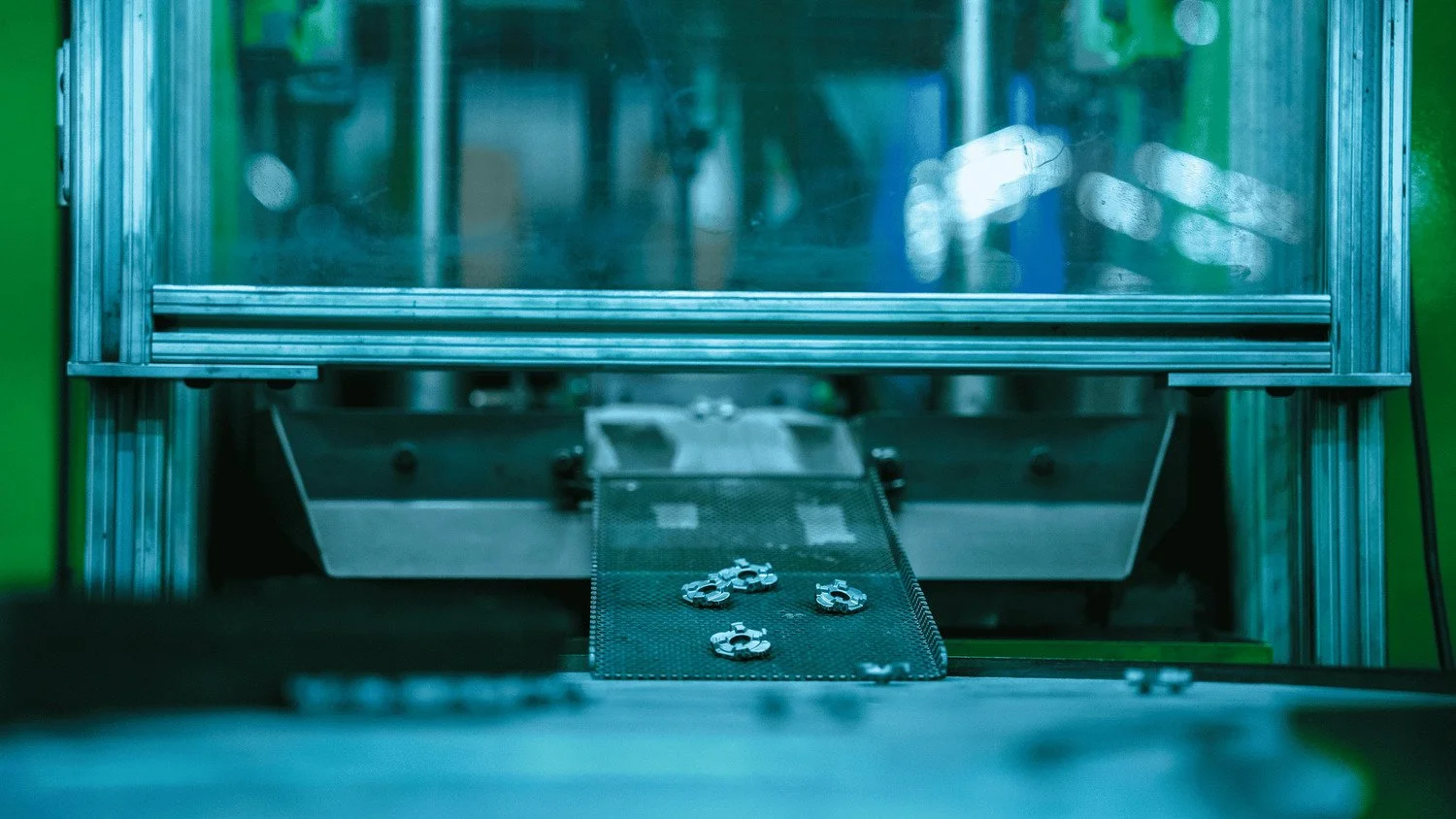

Exploring the Science Behind Sintered Metal Technology

Sintered metal technology shapes strong, precise parts by compacting and sintering metal powders. It cuts waste, boosts durability, and supports complex designs. Used in automotive, industrial, and heavy machinery, it delivers reliable, efficient components tailored for demanding conditions.

How Powder Metallurgy Enhances Industrial Manufacturing

Powder metallurgy forms strong, precise parts by pressing and sintering metal powders. It cuts waste, saves energy, and enables complex shapes. Industries like automotive, aerospace, and medical rely on its efficiency, tight tolerances, and consistent quality.

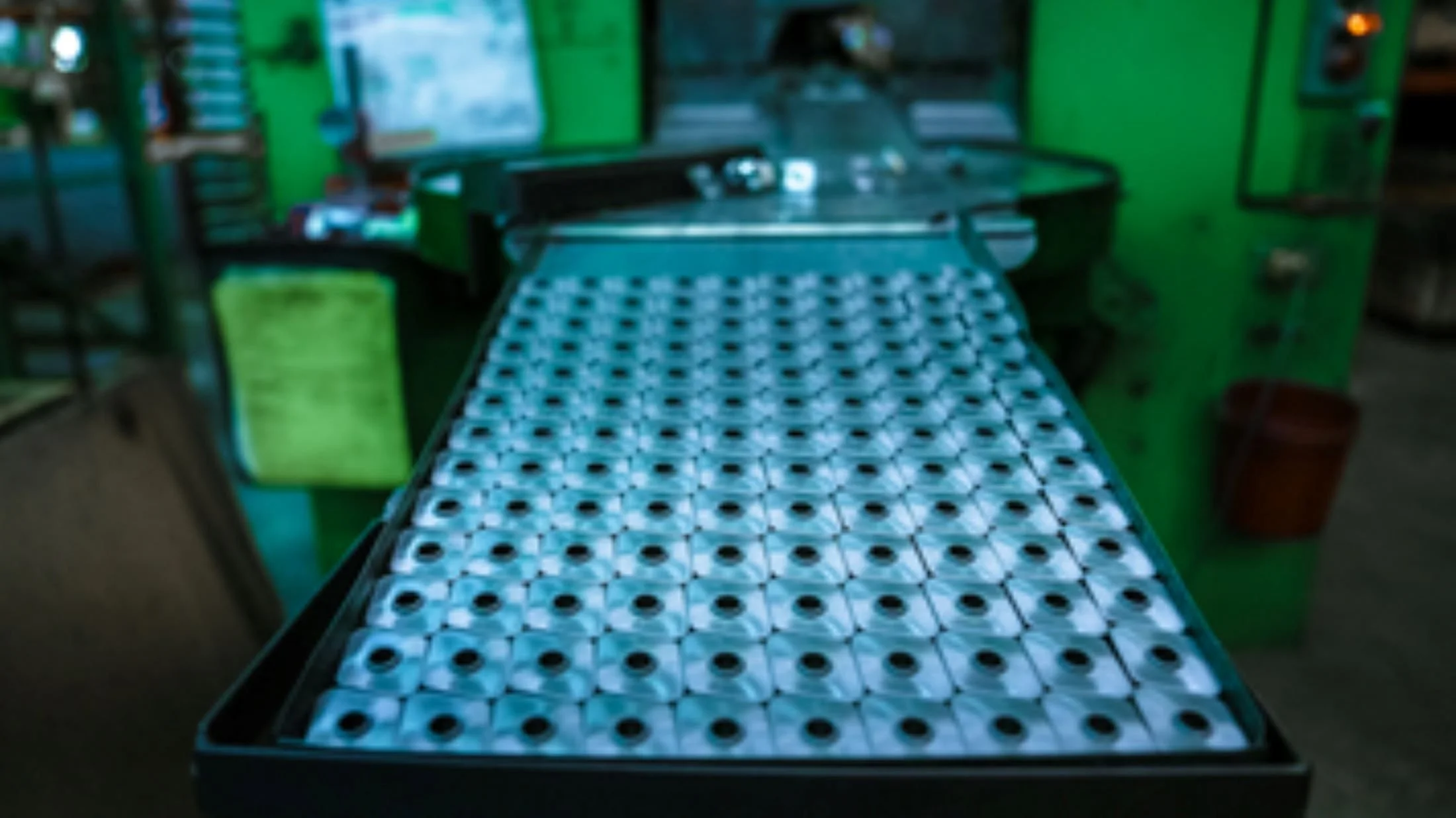

Why Industries Are Shifting Toward Sintered Metal Products

Sintered metal products deliver exceptional strength, precision, and consistency while reducing material waste and production cost. Their ability to achieve complex shapes and reliable performance makes them the preferred choice for industries seeking efficient, high-quality components.

Understanding the Strength and Durability of Sintered Metals

Sintered metals offer exceptional strength, precision, and cost efficiency across industries like automotive and aerospace. Their advanced manufacturing process ensures durability, reliability, and sustainable performance.

Exploring the Common Uses of Sintered Metal Products

Sintered metal products power industries from automotive to aerospace with durable, efficient, and precisely engineered components. Their strength, design flexibility, and sustainability make them essential in modern manufacturing and innovation.