Custom Powder Metal Engineering Solutions to Complex Challenges

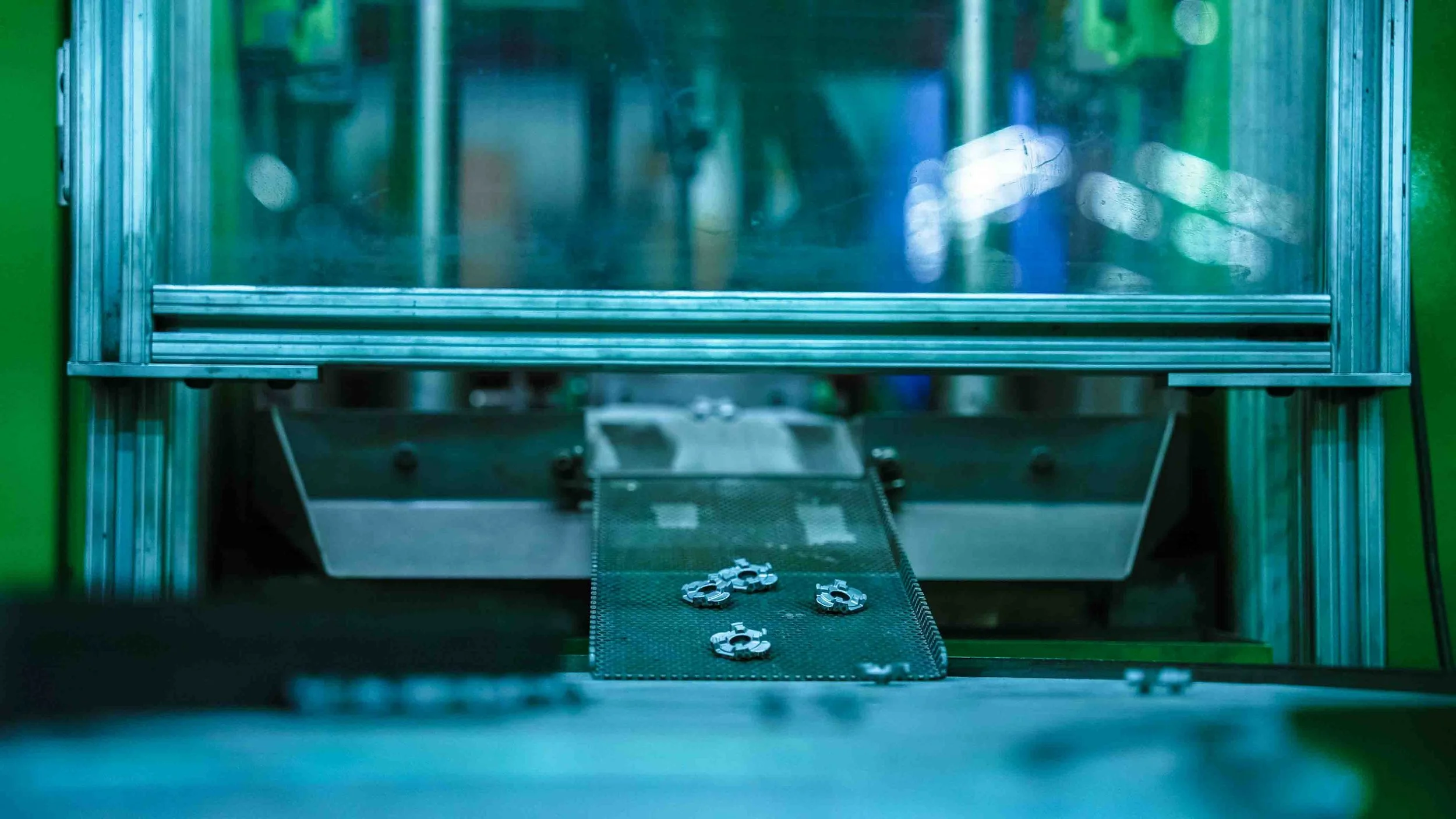

At Volunteer Sintered Products, our powder metal engineering solutions are designed to solve complex manufacturing challenges with precision, strength, and efficiency. From concept development to full-scale production, our experienced engineering team works closely with you to deliver high-performance components that meet demanding industry standards.

Precision Powder Metal Engineering You Can Rely On

Our powder metal engineering process combines advanced technology, innovative design methods, and high-quality materials to produce components with exceptional accuracy and durability. Whether you require custom-engineered parts or high-volume production, we ensure consistent performance across every application.

We proudly support industries including automotive, construction and agricultural machinery, powersports vehicles, and outdoor power equipment with tailored engineering solutions that meet exact specifications.

Request a quote or ask a question

Our Powder Metal Engineering Approach

Engineering Collaboration from Concept to Production

Every successful component starts with a strong engineering foundation. Our team follows a structured, hands-on engineering process to ensure optimal design, material selection, and long-term performance.

We collaborate closely with your team to analyze requirements, simulate performance, validate feasibility, and refine designs before moving into full production. This approach reduces risk, improves efficiency, and ensures reliable results.

Innovative Powder Metal Design & Development

Our powder metal engineering expertise allows us to create complex geometries and precision components that traditional manufacturing methods cannot easily achieve. Through advanced powder metallurgy techniques, we help reduce material waste, improve part consistency, and enhance overall performance.

From new part development to converting existing components into powder metal solutions, our engineers focus on durability, cost-effectiveness, and manufacturability at every stage.

New Design Process

To create the perfect component for your application, you’ll go through our hands-on “new design” process.

Step 1: Process and Design Collaboration

Step 2: PFMEA and Part Simulations

Step 3: Provide Prototypes for feasibility validation

Step 4: Refine design and optimize material selection

Step 5: Production tooling

Step 6: Product Qualification & Production Validation & Testing

Industries we serve

To create the perfect component for your application, you’ll go through our hands-on “new design” process.

Automotive Industry

Precision powder metallurgy parts enhance automotive systems with durable, high‑strength components for reliable top performance.

Construction & Agricultural Machinery

Precision powder metallurgy parts enhance construction and agricultural machines with durable, high‑strength components for extra efficiency.

Powersports Vehicles

Precision powder metallurgy parts enhance powersports vehicles with durable, high‑strength components for reliable performance offroad.

Outdoor Power Equipment

Precision powder metallurgy parts enhance outdoor power equipment with durable, high‑strength components for performance in yard tasks.

Conversion Projects Process

Our unique conversion engineering process saves you money, reduces your time to market, and improves your precision components.

Why Choose Volunteer Sintered Products

At Volunteer Sintered Products, we combine decades of engineering experience with advanced powder metal technologies to deliver dependable, high-quality components.

Experienced Engineering Team: Our engineers specialize in solving complex design challenges with proven powder metal solutions.

Precision & Consistency: We maintain strict quality standards to ensure every component meets exact tolerances.

Cost-Effective Manufacturing: Powder metallurgy enables efficient production with minimal waste and reduced secondary operations.

Industry-Focused Solutions: We serve automotive, agricultural, construction, powersports, and outdoor power equipment industries with tailored engineering support.

Where to Find Us

Volunteer Sintered Products operates from our state-of-the-art manufacturing facility in Tennessee, allowing us to efficiently serve customers across the United States and beyond.

Frequently Asked Questions

-

Powder metal engineering is the process of designing and manufacturing components using powdered metal that is compacted and sintered to achieve precise shapes, strength, and durability.

-

Powder metal parts offer excellent dimensional control, reduced material waste, cost-efficient production, and the ability to create complex shapes.

-

Industries such as automotive, construction and agricultural machinery, powersports, and outdoor power equipment commonly use powder metal components.

-

Yes. Our engineering team designs fully customized powder metal components based on your performance, strength, and application requirements.

-

Yes. Powder metallurgy is a highly efficient process that minimizes waste and supports sustainable manufacturing practices.