Revolutionize Your Industry with Advanced Powder Metal Solutions

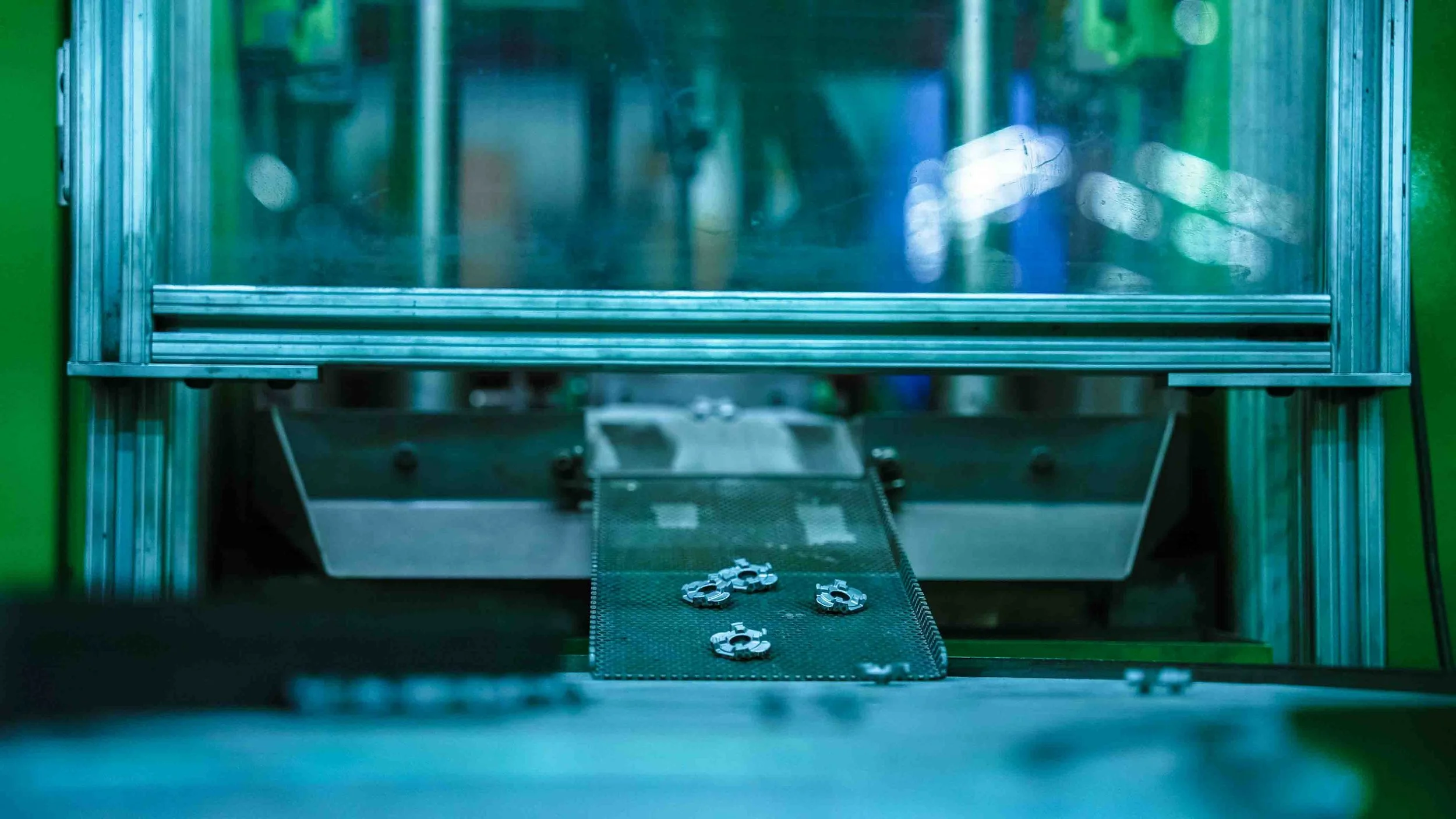

For more than 45 years, Volunteer Sintered Products (VSP) has partnered with leading manufacturers to deliver innovative powder metal solutions that outperform traditional manufacturing methods. Our advanced powder metallurgy capabilities allow us to engineer complex, high-performance components with superior precision, durability, and efficiency.

Powder Metal Solutions for Excavation & Agricultural Machinery

Enhance off-highway and agricultural equipment with powder metal components engineered for strength, reliability, and long service life. Our expert engineers work closely with manufacturers to develop durable solutions that withstand extreme operating conditions while reducing downtime and maintenance costs.

Key Components Include:

Transmission clutch rings

Large precision-finished mechanical components

Spur gears and gerotors for engines and transmissions

High-pressure sealed components for fluid, air, and vacuum systems

Oil and fuel transfer pump components

Steering vane pumps and braking components

ABS and differential components

Request a quote or ask a question

High-Performance Powder Metal Solutions for Automotive Applications

Engineered Automotive Components for Strength, Efficiency, and Reliability

Volunteer Sintered Products provides precision-engineered powder metal components designed to meet the rigorous demands of modern automotive applications. Our advanced powder metallurgy processes enable the production of complex, high-strength parts with tight tolerances and consistent quality. By optimizing material selection and component design, we help manufacturers improve fuel efficiency, reduce overall vehicle weight, and achieve long-term reliability across powertrain, transmission, steering, and drivetrain systems.

Automotive Components We Produce:

Steering components

Variable vane pumps

VVT / VCT components

Sprockets and transmission gears

Assembled camshafts

Seating and differential components

Powder Metal Solutions for ATV & Off-Road Vehicles

ATV and off-road vehicles demand components that perform reliably under extreme terrain and impact conditions. Our powder metal solutions deliver unmatched durability, precision, and power efficiency for off-road applications.

Using lightweight aluminum and soft magnetic composites (SMCs), we help manufacturers optimize power output while reducing overall system weight.

Common Applications Include:

Drivetrain components

Transmission gears and sprockets

Differential components

Shock and suspension mounts

Frame and chassis brackets

Brake system components

Electric motor soft magnetic composites (SMCs)

Winch mounting brackets

For more than 45 years, VSP has partnered with industry leaders across diverse markets, transforming complex concepts into innovative powder metal solutions not possible with other technologies. Our expertise in advanced metallurgical and engineering ensures your success in a competitive landscape.

Excavation and Agriculture Machinery

Collaborate with our expert engineers to enhance your off-highway and agriculture equipment with durable components. Our solutions provide increased reliability and longevity, reducing downtime and maintenance costs.

Transmission Clutch Rings, Large Finished Mechanical Components

Large Precision Finished Spur Gears and Gerotors for Engine, Transmission, and Final Drive Lubrication

High-pressure Sealed Components for Fluid, Vacuum, and Air

Finished Oil and Fuel Transfer Pump Components

Steering Vane Pump and Braking Components

ABS Components

Differential Components

Steering Vane Pumps

Braking Components

& More

Automotive

Leverage our powder metal solutions to enhance automotive components with precision and efficiency. Our advanced powder metal process delivers high-performance automotive components that improve vehicle performance and fuel efficiency. Lightweight aluminum offers significant weight reduction benefits. This makes our components ideal for manufacturers aiming to meet stringent emissions regulations while maintaining robust performance standards.

Steering Components

Variable Vane Pump

VVT/VCT Components

Sprockets

Assembled Camshafts

Transmission Gears

Seating Components

Differential Components

& More

ATV and Offroad Vehicles

Utilize our powder metal solutions to enhance ATV and off-road vehicle components with unmatched durability and precision. Our advanced powdered metallurgy processes deliver high-performance parts that improve terrain handling, impact resistance, and power efficiency. Lightweight aluminum and soft magnetic composites (SMCs) provide weight reduction and optimized power output, making our components ideal for manufacturers looking to maximize off-road capability while maintaining superior performance in extreme conditions.

Drivetrain Components

Transmission Gears & Sprockets

Differential Components

Shock & Suspension Mounts

Frame & Chassis Brackets

Brake System Components

Electric Motor Soft Magnetic Composites (SMCs)

Winch Mounting Brackets

& More

Outdoor Power Equipment/Lawn & Garden

VSP provides custom powder metal solutions tailored for outdoor power equipment and lawn and garden applications, delivering unmatched engineering expertise. Our solutions improve product durability and user satisfaction.

Clutch Components

Blade Adapters

Linkages

Steering Components

Self-Propelled Applications

& More

New Design Process

To create the perfect component for your application, you’ll go through our hands-on “new design” process.

Step 1: Process and Design Collaboration

Step 2: PFMEA and Part Simulations

Step 3: Provide Prototypes for feasibility validation

Step 4: Refine design and optimize material selection

Step 5: Production tooling

Step 6: Product Qualification & Production Validation & Testing

Our Sintered Metal Manufacturing Process

Our sintered metal manufacturing process combines precision engineering with advanced technology to produce components that meet exact performance standards.

Why Choose Volunteer Sintered Products for Powder Metal Solutions

Choosing Volunteer Sintered Products means partnering with a trusted leader in powder metal engineering and manufacturing with decades of proven performance. Our commitment to quality, precision, and innovation ensures you receive solutions that deliver strength, reliability, and lasting value.

Decades of Expertise: With over 45 years of experience in powder metal solutions, we combine technical mastery with real-world engineering insight to solve complex manufacturing challenges.

Advanced Manufacturing: Our state-of-the-art powder metallurgy processes produce high-strength components with tight tolerances and consistent quality — ideal for demanding industrial applications.

Custom Engineering Support: We work closely with your team from design to production, ensuring components are tailored to your specifications and optimized for performance.

Wide Industry Reach: Our solutions serve automotive, agricultural, construction, powersports, and outdoor power equipment applications, helping manufacturers improve durability, efficiency, and lifecycle performance.

Cost-Effective Results: By leveraging powder metallurgy efficiencies, we help reduce material waste, lower production costs, and deliver parts that often minimize the need for secondary machining.

Where to Find Us

Volunteer Sintered Products is conveniently located in Tennessee, operating from a modern, fully equipped manufacturing facility that allows us to serve customers across the United States and beyond with responsive support and reliable delivery.

Whether you’d like to discuss a new project, request a quote, or visit our facility, our team is ready to assist you and show how our powder metal solutions can meet your production needs.

Frequently Asked Questions

-

Powder metal solutions involve the design and manufacturing of components using powdered metals that are compacted and sintered to form precise, high-strength parts. This process allows complex shapes, consistent quality, and reduced material waste.

-

We serve a wide range of industries including automotive, construction, agricultural machinery, powersports vehicles, and outdoor power equipment. Our solutions are engineered to improve performance, durability, and efficiency in each application.

-

Yes. VSP offers fully customized powder metal solutions, tailored to your specifications, operating conditions, and performance requirements. Our engineers collaborate with your team from concept to production.

-

Sintered metal components are widely used in automotive, aerospace, medical, industrial machinery, and power tool applications due to their durability and precision.

-

Powder metal parts provide high strength, excellent dimensional accuracy, cost-effective production, and reduced material waste. They can achieve shapes and tolerances that are difficult or impossible with traditional metalworking methods.

-

Every component undergoes rigorous engineering, simulation, prototyping, and testing processes. Our advanced powder metallurgy techniques and quality control systems ensure consistent, high-performance parts for demanding applications.