Precision Sintered Metal Parts for High‑Performance Applications

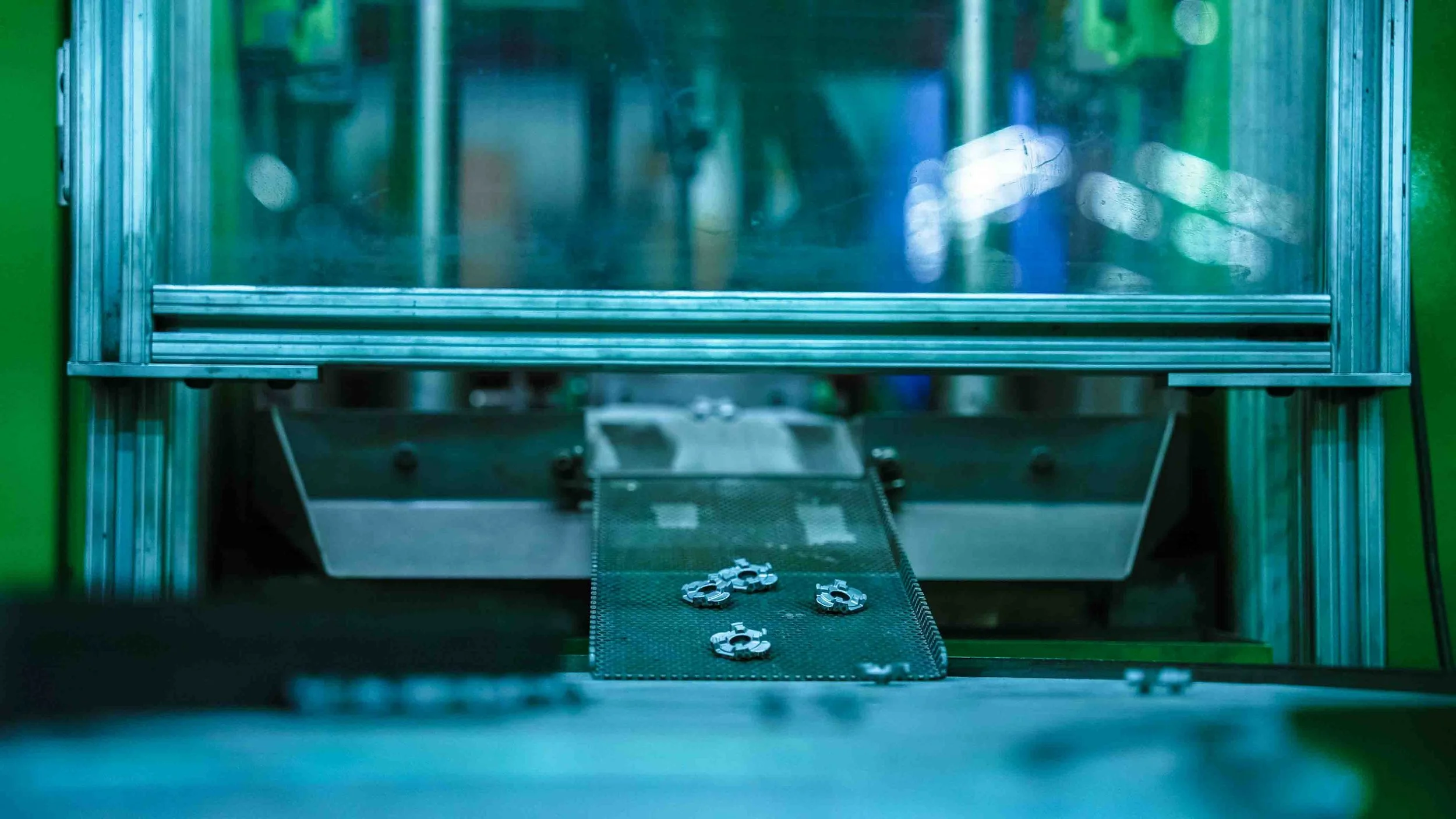

At Volunteer Sintered Products, we deliver precision‑engineered sintered metal parts designed to meet the most demanding performance, durability, and reliability requirements. Our sintered metal parts are manufactured using advanced powder metallurgy techniques, ensuring consistent quality, excellent mechanical strength, and cost‑effective production for industries ranging from automotive to industrial machinery.

What Are Sintered Metal Parts?

Sintered metal parts are components created through a process called powder metallurgy, where finely powdered metals are compacted into a die and then heated (sintered) until the particles fuse into a solid, durable piece. This method enables the creation of parts with:

Exceptional dimensional accuracy and repeatability

Superior mechanical strength and wear resistance

Complex shapes without extensive machining

Reduced material waste and lower production costs

This combination of performance and efficiency makes sintered metal parts ideal for demanding industrial applications where precision and reliability are essential.

Request a quote or ask a question

Our Sintered Metal Parts Capabilities

Customized Solutions for Every Application

Whether you need intricate components with complex geometries or robust parts built for heavy‑duty use, VSP delivers sintered metal parts tailored to your specifications. Our expert engineering team works closely with you from initial concept through final production to ensure parts meet exact performance, strength, and dimensional requirements.

Precision Manufacturing: Tight tolerances and consistent quality

Mechanical Strength: Engineered for high‑stress and high‑load conditions

Design Flexibility: Complex features and near‑net shapes are achievable

Reduced Waste: Efficient use of material with minimal scrap

Cost‑Effective Production: Lower overall manufacturing cost for medium‑to‑high volume runs

Key Advantages:

Our Sintered Metal Solutions

We specialize in providing custom sintered metal parts that meet the highest industry standards. Whether you're looking for small, intricate components or larger, robust parts, our powder metallurgy process ensures precision and consistency throughout production. Each sintered metal part is engineered to offer superior mechanical strength and long-lasting durability.

Our team works closely with clients to fully understand their needs and deliver tailored sintered metal solutions. From concept to final product, we ensure that you receive the perfect engineered component for your application, on time and within budget, all while maintaining top-notch quality across the nation.

How We Work

A Simple 6-Step Process for Quality Sintered Metal Parts

Step 1: Consultation – Understanding your needs

Step 2: Design & Planning – Creating accurate solutions

Step 3: Powder Preparation – Blending quality powders

Step 4: Compacting – Pressing into shape

Step 5: Sintering – Heating for strength

Step 6: Finishing & Delivery – Final touch & supply

Industries we serve

To create the perfect component for your application, you’ll go through our hands-on “new design” process.

Automotive Industry

Precision powder metallurgy parts enhance automotive systems with durable, high‑strength components for reliable top performance.

Construction & Agricultural Machinery

Precision powder metallurgy parts enhance construction and agricultural machines with durable, high‑strength components for extra efficiency.

Powersports Vehicles

Precision powder metallurgy parts enhance powersports vehicles with durable, high‑strength components for reliable performance offroad.

Outdoor Power Equipment

Precision powder metallurgy parts enhance outdoor power equipment with durable, high‑strength components for performance in yard tasks.

Conversion Projects Process

Our unique conversion engineering process saves you money, reduces your time to market, and improves your precision components.

Why Choose Us

Choosing us means gaining access to reliable quality, expert support, and cost-effective solutions for all your powder metal needs. Leveraging advanced technology and proven powder metallurgy techniques, we deliver sintered metal parts that meet the highest standards of performance, durability, and precision.

Our commitment is to build long-term relationships with clients by offering consistent service, competitive pricing, and tailored sintered metal solutions. When you partner with us, you gain a trusted ally dedicated to your business success, no matter your location. We Offer:

High-quality, durable sintered metal parts

Cost-effective powder metal solutions

Custom-engineered designs to meet your exact specifications

Reliable support and exceptional customer service, nationwide

Where to Find Us

You can find Volunteer Sintered Products conveniently located in Tennessee, where we operate our state-of-the-art manufacturing facility. Our location allows us to efficiently serve clients across the United States and beyond, providing reliable delivery and responsive support. Whether you’d like to discuss a new project, request a quote, or visit our facility, our team is always ready to assist you. Connect with us today to learn more about how our sintered metal engineering solutions can meet your production needs.

With decades of experience and modern technology, we ensure that every collaboration leads to long-term success. Reach out today and discover how our sintered metal expertise can power your next project.

Frequently Asked Questions

-

Sintered metal parts are used in automotive, aerospace, machinery, and many other industries for their strength, durability, and precision in applications like gears, bearings, and structural components.

-

Yes, sintered metal parts are highly durable and strong. The sintering process fuses metal powders into dense components, providing excellent mechanical strength for demanding applications.

-

Sintered metal parts are made by compressing fine metal powders into a mold and then heating them just below the melting point. This process, known as sintering, causes the particles to bond, forming solid, durable parts.

-

Yes, sintered metal parts can be customized to meet specific design requirements. The powder metallurgy process allows for the creation of complex shapes and tailored material compositions to suit different applications.

-

Sintered metal parts offer cost-effectiveness, high precision, and minimal waste during production. They also provide long-lasting performance, high strength, and the ability to create complex shapes that are difficult to achieve with traditional methods.