Exploring the Science Behind Sintered Metal Technology

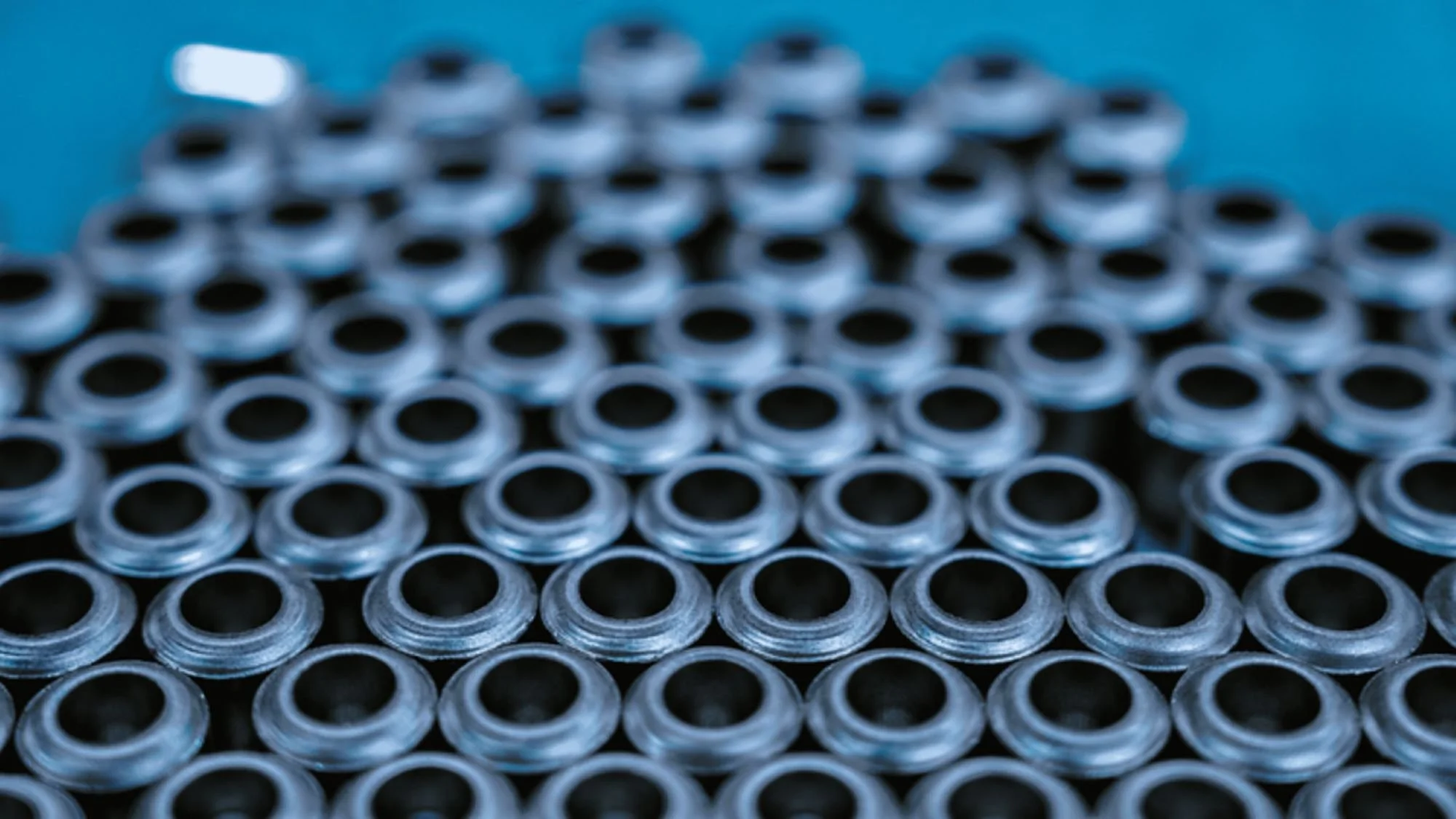

Sintered metal technology is quietly transforming modern manufacturing. It lets engineers craft components that are tough, precise, and built to last. The process, basically compacting powdered metals and heating them until they fuse, sounds simple, but it’s actually a game-changer. It sits at the heart of powder metallurgy, and pops up everywhere, from automotive parts to heavy industrial machinery.

I’ve noticed these products bring surprising advantages. Durable, shape-retaining, and consistent, this metal technology can sculpt intricate shapes with minimal material waste. Manufacturers love it because it streamlines production and cuts down on waste.

Understanding Sintered Metal Solutions

In modern manufacturing, Sintered Metal Solutions are crafted to meet very specific project needs. These aren’t one-size-fits-all parts. Each solution blends strength, accuracy, and operational efficiency. And the cool part is that every piece is built to endure rough conditions while performing the same, consistent way every time.

The Manufacturing Process

It all kicks off with high-grade metal powders, handpicked for properties. These powders get compacted into shapes that are close to their final design using advanced machines. This compaction ensures a uniform density and reduces flaws, basically laying the groundwork for a strong, reliable part.

Next, the magic happens, sintering in controlled furnaces. Heat merges the metal particles without completely melting them. It’s fascinating, this step actually strengthens the part, boosts toughness, and extends its lifespan. The components keep precise dimensions and perform reliably under stress. Plus, sintering minimizes shrinkage and warping. To be fair, the extra care at this stage is what really makes the difference between a good part and an exceptional one.

Customization and Applications

One of the things I find most impressive is how flexible these parts are. This metal can be tailored for exact uses. Automotive gears, bearings, and structural components gain durability and precision. Industrial machinery relies on them to handle heavy, continuous work. And specialized tools need these parts to perform consistently without hiccups.

Material efficiency is another huge win. Powder metallurgy produces way less waste than casting or machining. Extra powder can often be recycled, saving money and reducing environmental impact. Engineers can also shape complex geometries directly during sintering, which cuts down on post-production labor. All in all, it’s a smart use of time and resources.

Applications Across Industries

Sintered metal technology isn’t just for cars, although that’s a big chunk of it. Automotive components, engine parts, transmission gears, and brake systems become lighter, tougher, and more precise.

In industrial machinery, bearings, bushings, and structural components rely on this advanced metal technology for long-term performance under constant stress. Agricultural machinery, too, benefits from these parts, which can take serious strain over long periods. Basically, these components extend the lifespan of machines and reduce downtime.

Outdoor power equipment and powersports vehicles also exploit advanced metal for things like gears, sprockets, and fasteners. Even in extreme weather or rough conditions, these components hold up. Precision and durability keep operations smooth and minimize unexpected failures. It's pretty impressive how much these parts reduce delays and improve efficiency overall.

Advanced Sintered Metal Engineering

Sintered Metal Engineering is all about designing parts for peak performance. Engineers examine load, wear, and stress to pick the best materials and shapes. Advanced simulations are run to anticipate how parts will behave before even producing them. Every design iteration gets fine-tuned, making the final product as efficient as possible.

Prototyping and Production

First, prototypes are made to check functionality and durability. Once everything passes inspection, designs move to production tooling for large-scale runs. Quality checks happen at every stage, making sure the parts meet rigorous standards. Catching potential flaws early is crucial because nobody wants a defective component making it into production.

Material Customization

Advanced metal engineering also allows precise tailoring of materials. Powder blends can be tweaked for strength, wear resistance, or thermal performance. Designers balance cost with functionality to hit exact specs. Parts are built to endure tough conditions, and engineers can even adjust microstructures for extra longevity.

Companies that adopt this advanced engineering approach really gain a competitive edge. They can craft high-performance parts faster than traditional methods. Reliability and consistency become standard across production lines. Even existing components can be upgraded; engineers analyze the original, suggest improvements, and refine the design. Often, the new parts outperform the originals in strength and dependability.

Benefits of Sintered Metal Technology

Sintered Metal Solutions

Metal components pack a lot of benefits. Strong, precise, and long-lasting. Complex shapes can be made without heavy machining, saving both time and money. Parts also resist wear and hold their shape over time.

Material efficiency is a big deal here. Powder metallurgy wastes far less than casting or machining. Recyclable powders add a sustainability bonus. Tight tolerances also make sure components perform reliably in automotive, industrial, and specialty applications.

Another thing I’ve noticed: customization is a huge strength. These metal components can be engineered for specific loads, wear patterns, and environments. Designers get to optimize performance while keeping costs in check. Components are resilient, tailored, and built to last. It’s no wonder manufacturers keep turning to this tech for reliability and efficiency.

Conclusion

Metal technology is reshaping manufacturing. It blends strength, precision, and efficiency in a way that just works. Components meet strict standards and perform well even under challenging conditions. From automotive to agriculture, industries depend on these solutions to keep operations running smoothly.

Volunteer Sintered Products is leading the way in metal engineering. Expertise ensures every component meets specs and performs consistently. From concept to delivery, quality and innovation are at the core.

If you’re ready to see how Powder Metal solutions can elevate your next project, contact our team today. Partner with experts who understand high-performance, cost-efficient, and reliable metal components.